Concept Systems had a dynamic week in sunny Anaheim, California, at the 2024 Rockwell Automation Fair this November. The event sparked valuable conversations with new connections across the Southwest and strengthened relationships with our long-standing partners.

Chad McDowell, Technical Resource Director, participated in a panel at the inaugural New Capacity Summit, where he emphasized the critical role of system integrators in greenfield operations. As manufacturers gear up for projects driven by initiatives like the U.S. Infrastructure Investment and Jobs Act and the RAISE program, Chad highlighted how early integrator involvement ensures smoother, on-time project execution. Read more in Control Global’s article, “ Involve integrators early on new capacity projects | Control Global

Evan Gonnerman, Portfolio Manager, continued his product showcase of evriiRobot and its integration with Rockwell’s FactoryTalk® Optix™, a key feature in our modular robotics solutions. In his two sessions, “Enhancing Automation with Configurable Operator Consoles Using FactoryTalk Optix,” Evan demonstrated how adaptive consoles can reduce costs and improve quality, offering a fresh take on modular automation.

Our team brought diverse perspectives to this year’s sessions and opportunities—read their insights below!

Bob O’Brien, a Principal Controls Engineer with over 20 years at Concept Systems, is known for bringing energy wherever he goes. At the Happiest Manufacturing Hour event, Bob enjoyed reconnecting with familiar faces from past “rodeos” and making new connections—proving once again he’s the life of every party.

“The keynote speakers had a big focus on AI and how it WILL affect modern manufacturing. It was very insightful to get a glimpse of Rockwell’s vision of the future where data will impact the low-level machines, and active feedback will automatically adjust machines to improve quality.

I specifically enjoyed the keynote presentation about the trials and tribulations of the LEGO company. The boom-and-bust swings that went from raking in profits to near bankruptcy were fascinating. I particularly liked the business warning that just because it worked before doesn’t mean it will work again. Companies, such as system integrators, need to be nimble and constantly on the lookout for new opportunities and pitfalls.

It was interesting to see Rockwell’s robotic implementation based on Kinetix 5700 servos and Comau robot hardware. I attended the lab session that showed how to configure the robot environment within Studio 5000. WOW – a lot of work has been put into this effort.

I strongly recommend all Concept engineers make it to an Automation Fair event just to see firsthand how large and encompassing the Rockwell brand truly is.”

Mike Williams, our Southwest Regional Sales Engineer, was glad to have this year’s Automation Fair on his home turf. In addition to connecting with his current customers, he joined the facility tour at Papé to experience Rockwell’s OTTO demonstration firsthand.

“It was great hosting Automation Fair in Anaheim—the sunshine was a nice change for many out-of-state customers and vendors. Being based in Southern California, it was easy to bring my local customers out to see Rockwell’s latest technologies and spend time with our engineering team beyond ongoing projects.”

Rockwell has a strong presence in SoCal, and working with local distribution vendors is always a pleasure. We had great conversations about everything from control upgrades to robotic applications, with plenty of future-focused ideas. Evan’s presentation sparked interest in how evriiRobot can tackle areas—like part feeding—that engineering teams often overlook.

Over the next few weeks, we’ll be following up with customers across industries like automotive, food and beverage, and pharmaceuticals. It’s exciting to hear how many have already embraced automation and are now looking to partner with us on additional opportunities.

Jordan Meader, Controls Engineer, embraced every opportunity the event had to offer, bringing back valuable insights for the team. His growth mindset and knack for picking up new information made his experience both enriching and inspiring. His excitement is evident in his reflections below:

“The event was massive—the sheer scale of the expo and the technology on display was inspiring. The labs were incredibly helpful, offering hands-on exposure to the software environment and deep dives into lesser-known features. I made plenty of new industry connections, including our Rockwell Account Manager, Mike Dodds at Delta, Fanuc engineering support, North Coast support, and Gray Solutions.

FactoryTalk® Optix™: Asteroid Mining

He continues: “The FactoryTalk Optix lab was a standout. The futuristic manufacturing scenario of managing resources on a ‘ship’ kept me engaged while learning to generate new HMI displays to ensure operational safety. The lab was thorough, easy to follow, and perfect for new Optix users.

Had a lot of fun in this lab learning about FactoryTalk Optix. The approach to using a futuristic scenario in manufacturing made it easy to capture my attention. The lesson focused on repurposing limited resources within the ”ship” and generating new HMI displays to monitor that the changes were not causing any detrimental risks to the ”mission.” The lab was very thorough and easy to follow; I highly recommend for new Optix users.

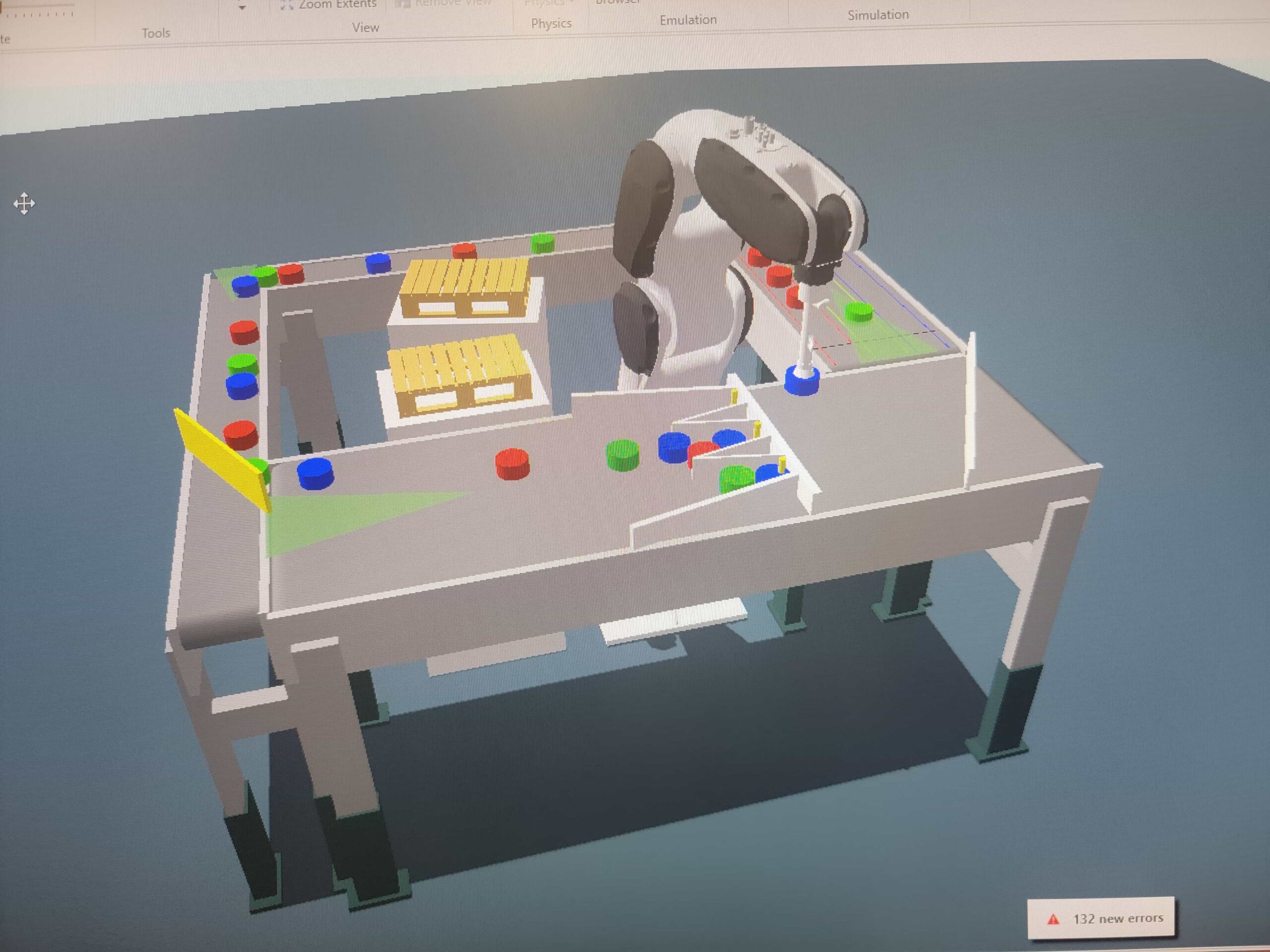

Rockwell Emulate 3D: Robot Arm Hockey Puck Sorting

“Using Emulate 3D was both challenging and rewarding. It’s a powerful tool for simulating a full robot cell integrated with a PLC and HMI. The lab was well-structured but required patience, with four interconnected programs to manage. Watching the simulation come together and seeing the robot’s performance in action made it all worthwhile.”

Jordan’s photos from the labs and his connections showcase the energy and excitement of the event, capturing how hands-on learning and networking made a lasting impact.

Finally, Evan Gonnerman used the conference as an opportunity to sharpen his controls skills and connect with industry leaders. His reflections capture the future-focused energy of the event:

“Industrial DevOps is no longer niche—it’s quickly becoming the expectation. The integration of Agile methodologies, version control, continuous integration, and deployment pipelines into automation systems is fundamentally transforming how we approach industrial environments. Tools like FactoryTalk Logix Echo, Optix, Design Studio, and the Logix SDK are making modern software architectures a reality, enabling more robust and scalable industrial solutions. This shift towards generative efficiency, driven by modular software architectures and AI copilots in platforms like FactoryTalk Design Studio, is pushing the boundaries of what’s possible in automation, making it feasible in areas where ROI was once too low to justify. Robotics, from robotic arms to mobile and humanoid systems, are further redefining automation. Their ability to dynamically adapt to market changes is driving the need for end-to-end, full-service automation solutions—from raw material unloading to finished product loading. As technology evolves, so must automation systems. With tools like FactoryTalk Remote Access, Data Ready Smart Machines, and Optix’s cloud connectivity, we are entering an era of ‘just-works’ automation, where adaptive, continuously refined solutions are not just a luxury—they’re an expectation.”

Evan’s reflections reveal a clear passion for innovation and the evolving landscape of automation. His takeaways point to an exciting future where cutting-edge technology and practical solutions converge.

This year, Concept Systems’ role as a sponsor and thought leader at the Rockwell Automation Fair made for a successful and impactful week. Our team engaged deeply in various sessions and labs, exploring the latest industry trends such as Industrial DevOps, modular robotics, and adaptive automation solutions. While our absence from the Expo Floor was a shift, it allowed us to focus on high-level customer engagement and knowledge-sharing.

We’re already strategizing for 2025 and are excited to continue building relationships across the Southwest. In February, we’ll be back in Anaheim for the MD & M show, showcasing a robotic workcell that highlights our commitment to innovative solutions. We look forward to seeing everyone at next year’s Rockwell Automation Fair in Chicago and continuing to shape the future of automation together.